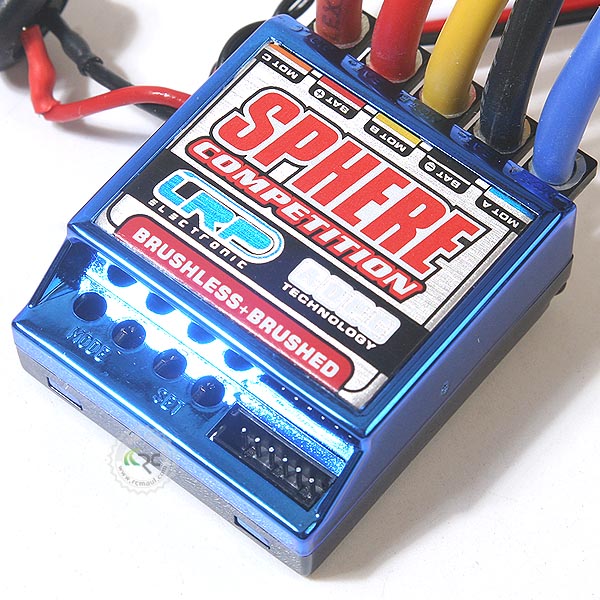

Features:

- Automatic Brushless/Brushed Adaptation

- ADVANCED Digital with 4 adjustable modes

- IceDrive Design

- Forward/Brake

- AutoCell System – NiMH-LiPo automatic adaptation

- Sensored Design

- Motorlimit Brushless: Over 3.5 tunrs

- Motorlimit Brushed: Over 5 tunrs

- 3.0A BEC

- Blue LED

- Small in size and weight (only 24.5g)

- Multi-Protection System

- Extrenal Solder Tabs

- 13AWG power wires

PDF: '2007 edition' IMPROVEMENTS

Order No. 80700 SPHERE COMPETITION '2007 edition' digital

Introduction

Many areas of the brushless technology are misunderstood and rumours and false information are pretty common when it comes to this issue, we’d like to shed some light into this and explain a few things about brushless technology which will possibly help you to make the right decisions in order to make this great hobby grow.

Situation of brushed motors today:

Most drivers are pretty much fed up how much maintenance is required to be competitive in electric racing. Cutting commutators and replace brushes has unfortunately become a must in competitive racing. It is not something the clubracer or novice likes to do and his wallet doesn’t like it either when motors and brushes wear out quickly! Spending in the range of €30 just for brushes for a race-weekend and continuously rebuild the motors is expensive and troublesome for racers at all levels. Additionally it keeps new customers away from entering the hobby.

Ever since low-turn motors are used, due to the continuous improvements in battery technology, there has been a new problem occurring. Armatures get out of balance or solder-joints become unsoldered at the commutator, due to the high rpms and the high current draw. An expensive 100€ modified motor can become “trash” within a few runs if this happens. The racer has no other choice then to buy a replacement armature or complete new motor!

There have been some improvements on this problem due to endbell design (V2 technology) and new brush compounds lately (LRP P-brush, etc.). These improvements reduce the maintenance of the motors, but to be competitive, there´s still the need of skimming the commutator and changing brushes regularly.

As stated before, one of the main reasons why all these issues have become more and more of a problem during the last 2 years are the latest developments in battery technology. Modern cells have such a low internal resistance and high capacity that average currents of over 35A are common. Spike currents in excess of 120A during acceleration are common! This just kills the brushed motors, which are fundamentally based on old-style technology and in some way are “outdated”.

Brushless Technology - Facts & Fictions...

Is brushless a new technology?

No, it isn’t! It was introduced in the early 90’s in airplanes/boats and is widely used there with no problems.

Actually the brushless technology made the electric classes grow over the nitro-classes in planes/boats in the last years.

The electric car market is the exact opposite, electric is shrinking and gas is growing.

So far, the brushless technology wasn’t promoted by the present electric car motor manufacturers and therefore wasn’t introduced to competition rc-car racing.

Is brushless much more expensive then brushed?

No! Initially the costs for a brushless system are only about 10-20% higher then a brushed system.

In the long run, the brushless system will be much cheaper since no replacement brushes, replacement armatures or comm-lathe are required by the racers!

Can brushed and brushless systems compete with each other?

Yes, of course! Power output and RPM are similar between the two systems.

In Off-Road, both systems will be equally competitive (power & runtime are no issue there due to lack of traction of the tyres!) with most likely an advantage for the brushed system due to the familiar feel and driveability for the driver.

In On-Road, there might be an advantage for the brushless system in efficiency and torque.

Will brushless motors & speed-controls be interchangeable between manufacturers?

Yes, this will be possible in a similar way as with current brushed motors, as long as the proposed rule by ROAR to IFMAR (see EFRA proposal below) will be adopted. The only exception will be, that sensored speed-controls will only be able to work with sensored motors. Sensorless speed-controls on the other hand, will work with sensored- and sensorless motors.

How does a brushless system work?

Simply speaking, the brushless motor is an “inside out” brushed motor with no commutator or brushes. The commutation (what is done by the commutator and the brushes in the brushed motor) is done electronically inside the speed-control. As there is no brush and no commutator, there is no wear.

Do brushless systems work reliable?

Yes. As seen in plane/boat applications, they’re probably even more reliable then brushed systems. Also the stuttering at low speeds, which 1st generation brushless systems had, are a thing of the past with modern brushless systems. New sensored brushless systems offer almost identical driveability as known brushed systems.

Do brushless motors fit into existing models?

Yes, of course! The systems, especially designed for cars by known “car system manufacturers” (like Novak or LRP) do perfectly fit into existing models. Pinions, spurs, etc. are exactly the same and can be used with brushless and brushed systems.

Do brushless motors wear out?

No, as there is no commutator and brush.

The only mechanically loaded parts in a brushless motor are the ball bearings. They need to be changed as in brushed motors.

Do brushless systems work with 4- to 6-cells?

Yes, they work as good as brushed systems with 4- to 6-cells.

Overview of several interesting facts/features of brushed and brushless systems:

| Fact/Feature: |

BRUSHED

|

BRUSHLESS

|

| Commutator cutting after (no. of runs) |

1 - 5*

|

Not needed

|

| Replacement of brushes (no. of runs) |

1 - 5*

|

Not needed

|

| Modified armature/rotor lasts for (no. of runs) |

1 - 80**

|

Unlimited

|

| Achievable "race"-runtime (with similar performance) |

5min

|

~6min

|

| Approximate power output |

~240W

|

240 - 280W

|

| Approximate maximum RPM level |

~42'000

|

40'000 - 45'000

|

|

|

|

|

| Completely rebuildeable? |

Yes

|

Yes

|

| Direct fit into all existing models and motor mounts? |

Yes

|

Yes

|

| Existing pinions can be used? |

Yes

|

Yes

|

| Motors and speed-controls interchangeable between manufacturers? |

Yes

|

Yes

|

| Approx. cost for a complete system (motor & speed-control)? |

~400€

|

~450€

|

* if regular competition motor is used.

** one run if armatures gets out of balance or solder becomes soft

50,000원 이상 주문시 무료배송! (단, 50,000원 미만 주문시 배송료 3,000원이 추가됩니다.)

- RC용품 제조사 A/S규정안내

- 변속기,배터리,모터,수신기 킷트 등의 모든 RC용품은 제조사의 공장 출고시 불량을 제외한 어떠한 경우에도 제조사의 규정에 의해 일체 교환 및 무료 A/S는 불가합니다. (알씨마을의 규정에 의한 것이 아니니 이점 이용에 참고하시기 바랍니다.)

- 최초 불량이 아닌 사용중 파손시 고객님께서 직접 수리 및 부품교환을 하셔야 하나 수리가 어려울 경우 알씨마을로 문의 주시면 부품 + 공임(공임은 작업량에 따라 약 1만~5만원)으로 유료 A/S(수리)를 해드릴 수 있습니다.

- 제 1 조 알씨마을의 부담으로 재배송 또는 반품, 교환, 환불해 드리는 경우

- 1. 주문한 상품과 다른 상품을 배송한 경우

- 2. 주문한 상품의 수량과 수령한 상품 수량이 다를 경우

- 3. 상품의 파손 손실된 상품을 배송한 경우

- 4. 상품(택배)을 받지 못했을 경우

- 제 2조 고객께서 비용을 부담 하셔야 하는 경우

- 1. 고객님의 변심으로 반품, 교환을 원하는 경우(단, 개봉한 상품은 불가)

- 2. 주문시 배송지 주소를 잘못 기입하여 배송받지 못한 경우

- 3. 주문시 호환여부를 잘못 판단하여 사용할 수 없는 상품을 주문한 경우

- 4. 수령한 상품을 사용중에 부품이 파손된 경우

- 5. 수령한 상품을 사용중 초기셋팅값을 변경하여 시동 또는 작동이 되지 않을시 유선상 처리가 불가한 경우

- 제 3 조 기타 유의 사항 안내

- 1. 알씨마을 쇼핑몰의 상품상세정보는 실제 상품정보와 약간의 차이가 있을 수 있습니다.

- 2. 옵션 상품등 호환되는 상품 주문시 꼼꼼히 호환여부를 확인 후 주문하시기 바랍니다.

- 3. 파손된 상품 또는 불량에 대한 이의 제기는 택배수령후 3일 이내에 하셔야 합니다.

- 4. 개봉한 상품은 반품, 교환되지 않습니다.

- 5. 반품, 교환시 배송중 파손될 경우 그 손해는 고객님께서 부담하셔야 합니다.

- 6. 구매자의 사용 미숙으로 발생한 신체 또는 재산상의 손해에 대하여 일체 책임 지지 않습니다.