The 2011 version of the highly succesful 808 platform brings major changes and improvements to bring performance, reliability and enjoyment again to another higher leve. With a focus on attaining maximum reliability of the platform, the central drivetrain system has been updated. To push performance levels higher, the suspension geometry has been improved once again, and new aluminum suspension holders are now included as standard in the kit. With XRAY몊 legendary dedication to small details and long-term extensive testing and feedback from Team XRAY drivers around the world, the 2011-spec 808 has been improved in every way.

With the Car of the Year award, Viewers Choice award, and countless wins and victories at racetracks around the world, XRAY presents the new and improved 2011-spec 808.

2011 XRAY 808 New Specs:

?New chassis to accomodate all new drivetrain parts

?New and improved handling

?New suspension geometry with multi-adjustable roll centers

?New improved weight balance with more centrally-positioned rotary moment

?New diff bulkheads to accomodate new drivetrain parts

?New central drivetrain system

?New central CVD drive shafts

?New pinion gears

?New diff ball-bearings

?New better-sealing shock O뻭ings

?New rear brace to accomodate new central drive shafts

?New front and rear alu suspension holders with eccentric roll centers

?New composite eccentric bushings

?New more robust suspension pins

?New high-downforce body

?New graphite radio plate more securely placed between throttle servo and spur gear

?New updated radio box

XRAY XB808 General Specs:

?premium high-competition off-road buggy

?efficient Zero Kingpin suspension

?lightweight & strong composite steering blocks with molded-in steel bushings

?well-proven 808 suspension parts and geometry

?ultra-low CG, all parts centralized in chassis

?optimized front/rear and left/right weight balance for perfect jumping

?pure racing design, highest performance, ultra-durable parts

?ultra-lightweight, high-tensile transmission parts hand-made from special world-renowned top-secret self-developed HUDY Spring Steel?

?drivetrain includes 22 high-speed rubber-sealed bearings for maximum efficiency and speed

?ultra-precision front/rear and center diffs with HUDY Spring Steel?outdrives

?pinions, spurs, crown gears and clutchbell manufactured by HUDY

?optimized multiple upper/lower shock mounting locations for front and rear

?steel brake disks for ultra-efficient, fade-free braking

?high-grip brake pads

?exclusive adjustable turnbuckles from HUDY Spring Steel?

?small profile steering blocks with molded-in steel bushings and ultra-light caster blocks

?high-tensile Swiss 7075 T6 hard-anodized chassis

?ultra-strong inboard & outboard suspension pivot pins

?front & rear anti-roll bars

?centralized engine positioning

?narrow servo saver and steering system

?ultra-short graphite steering plate

?front & rear flexible composite brace

?gearboxes with Labyrinth Dust Covers?

?clutchbell with oversized ball-bearings

?premium-grade graphite shock towers: 4mm extra-thick front, 3.5mm thick rear

?big-bore oversized shocks for excellent handling on bumpy tracks and big jumps

?threaded big-bore hard-anodized shock bodies

?protective rubber folding shock boots for big-bore shocks, front & rear

?super-low profile foam air filter with redesigned rubber elbow

?larger-capacity fuel tank with capacity-adjustment inserts

?fuel line holders mounted directly on fuel tank

?fuel tank pressure cap with 1-piece profiled seal for perfect fitment

?reinforced composite ball joints

?ultra-low XRAY racing body

?XRAY Premium Shock Oils for perfect consistency

?Winner뭩 pedigree ?European Champion, countless National and Championship titles, Multiple Car-of-the-Year awardsXRAY

808 General Specs:

The XRAY 808. The ultimate vehicle concept molded and shaped into an extraordinary engineering masterpiece by the artisans at XRAY. Superior as ever?yet all new. The 808 throws down a challenge for you to drive it?race it?win with it. Answer the call?take the challenge. Experience a new form of fascination, undreamed-of driving enjoyment?performance and dynamic ability you can count on. Experience the all-new XRAY 808.Since 2004 when XRAY released the first 1/8 off-road car, the XRAY XB8 platform has enjoyed great success both on & off the track. Praised by the RC press and media as well as customers themselves, the XB8 platform has been the recipient of multiple Car-of-the-Year awards. Along with numerous National titles around the world ?including the most prestigious European Champion title ?the XB8 has been one of the world뭩 most successful off-road cars. The mandate of the XRAY Development Team is to pursue perfection and innovation, while constantly developing and redefining the performance envelope. Through ongoing development and improvement, the 808 platform has evolved through different versions to the current 2011 spec version, with each version bringing improvements to surpass its predecessors.

Everything is new in the 808 platform drivetrain: all-new CVD drive shafts; all-new drivetrain layout; new direct central shaft connection to the pinion gears; all new ratios.

The 2011 version features new central CVD drive shafts with new pinion gear.

Since drivetrain weight and design have a significant influence on the handling and performance of the car, the drivetrain was completely redesigned and greatly improved. The new ultra-lightweight drivetrain has reduced rotating weight and increased performance. All drivetrain parts ?drive shafts, diffs, brakes, outdrives ?are ultra lightweight, strategically weight-reduced, and are manufactured from premium high-quality world-renowned HUDY Spring Steel?

Central Drivetrain

The central drive shafts are new for the 2011, and feature a CVD design and new pinion gears. The new 8x16 diff bulkhead ball-bearings are proven from the truggy drivetrain system, giving increased reliability to the 808 platform.

Diff Housings

Diff bulkheads are all-new for 2011 version. The diff bulkheads accomodate for the new central drivetrain system.

Radio Tray

The new radio tray creates more space between the throttle servo and spur gear. The radio box has been moved further away from the engine and central drive shaft.

The radio tray is CNC-machined from premium high-grade graphite material which ensures great strength while remaining very light. The front area above the steering servo features an opening for even more weight reduction.

The graphite radio tray features a laydown steering servo and upright throttle/brake servo arrangement; both servos have been moved towards the chassis centerline. Heavy-duty steering horns are included to withstand the abuse from long races.

The chassis was redesigned following the all-new weight distribution and centerline placement of internal parts for improved side-to-side weight balance.

The chassis is CNC-machined from high-quality 3mm-thick Swiss 7075 T6 hard-anodized aluminum which has been strategically machined in low-stress areas to make it as light as possible without affecting strength or rigidity. The chassis is hard anodized at XRAY’s own in-house fully robotic hardcoating line, ensuring a perfect hardcoated surface.

Non-essential material below the engine, fuel tank, and diffs was removed to allow for the lightest weight and lowest possible center of gravity.

The downstop setscrew area is reinforced. All screw holes on the bottom of the chassis are countersunk, giving a very smooth chassis underside with no protruding screw heads.

Strong composite side guards help protect the internal components.

Suspension

The most significant handling improvement was achieved by all-new suspension components and geometry. The suspension concept was carried over from 1/10 electric off-road cars — redesigned and adapted for 1/8 off-road, incorporating XRAY’s innovative ideas and reducing the size of the components used. The suspension geometry was fine tuned to give the car super-easy handling under all racing conditions.

Suspension Arms

Suspension arms are one of the most important parts of any RC model car, as they directly influence the handling and racing characteristics of the car. The 808 suspension arms are all-new and the final design is the result of long-term tests of different designs and layouts. Length; thickness; flexibility; geometry of suspension points; materials used… these are all the concepts and details that had to be thoroughly reviewed to create optimum suspension arms.

Based on excessive knowledge gained from previous XB8 platforms, several different suspension arm designs were tested in both virtual reality and in-car to find the best design. The exclusive composite mixture used for suspension arms is a perfect balance between reliability and performance. The suspension arm itself is rigid enough to provide a responsive feel, yet soft enough to survive extra-long racing events.

The new aluminum suspension holders feature square eccentric bushings to allow complete suspension geometry adjustment and roll center adjustment.

Suspension arms and suspension geometry give increased steering, influenced by different Ackermann characteristics.

The angle of the tires during steering does not change as much as it does on the standard C-hub or pivot-ball suspension. Even when the suspension moves up or down the suspension ensures constant steering for easier, more precise and predictable handling into and within corners, and especially ensures fluid drive through the corners (important on bumpy tracks).

Shocktowers and shocks were redesigned accordingly to complement the new suspension geometry.

Zero Kingpin Steering Blocks

The super-lightweight composite Zero Kingpin steering blocks are a genuine innovation in design and functionality. Each block features an inset steel bushing that is molded into the steering block itself, ensuring a wobble-free and ultra-tight steering block assembly.This enables the kingpin screws to be firmly held in the steel threaded bushing while the end of the screw is self-locked in composite to prevent the screws from loosening during racing. The molded-in steel bushings allow the steering blocks to turn freely, ensuring precise steering action. The super-tiny steering blocks are molded from lightweight, very strong and durable composite material.

Lightweight Suspension Blocks

The new-concept steering block is taken from 1/10 electric off-road cars, providing zero kingpin steering — the steering block rotates in an absolute vertical position so that the angle does not change. The new steering block gives a better steering radius which greatly improves the handling and makes the car even easier to drive on all tracks and provides more

steering into corners. The steering block features a single optimized Ackermann position.

The tiny size of the steering blocks was achieved by using new lighter ball-bearings. The inner bearing (13x19) carries a heavier load where the CVD drive shaft outdrive rotates, while the outer bearing (8x14) is newer & lighter than before to reduce unsprung weight. The two ball-bearings are further away from each other which improves stability in the mounting and holding of the wheel axles.

Each 1-piece lightweight caster block has the new zero kingpin suspension geometry, and each car is equipped with an optimum preset 10° caster block. The optimized caster angle is integrated and non-adjustable. The angle of the caster block + 10° angle of the front chassis kick-up with the suspension holders = total 20° caster.

Rear Uprights

New uprights were designed to have a more compact and lighter design. The lower roll center position has been optimized to 1 position while the upper roll center positions still feature 3 different positions.

The tiny size of the upright was achieved by using new lighter ball-bearings. The inner bearing (13x19) carries a heavier load where the CVD drive shaft outdrive rotates, while the outer bearing (8x14) is newer & lighter than previously used to reduce unsprung weight. The two ball-bearings are further away from each other which improves stability in the mounting and holding of the wheel axles.

The outer suspension pin on which the rear upright sits features 2 shims which allow for additional wheelbase adjustment.

Chassis Braces

The front and rear braces have a significant influence on chassis stiffness and flex, and as such have a great impact on car handling under different grip conditions. The 808 features well-proven and optimally stiff composite braces for front and rear. These braces are more than up to the task… strong enough to hold the car together after heavy jumps or crashes to avoid tweak or breaking, yet still flexible enough to generate the needed grip.

Shocktowers

Front and rear shocktowers are all-new. The shocktowers are CNC-machined from premium extra-robust 4.0mm (front) and 3.5mm (rear) high-grade graphite which significantly reduces the weight. The shocktowers feature optimized shock positions and roll center positions.

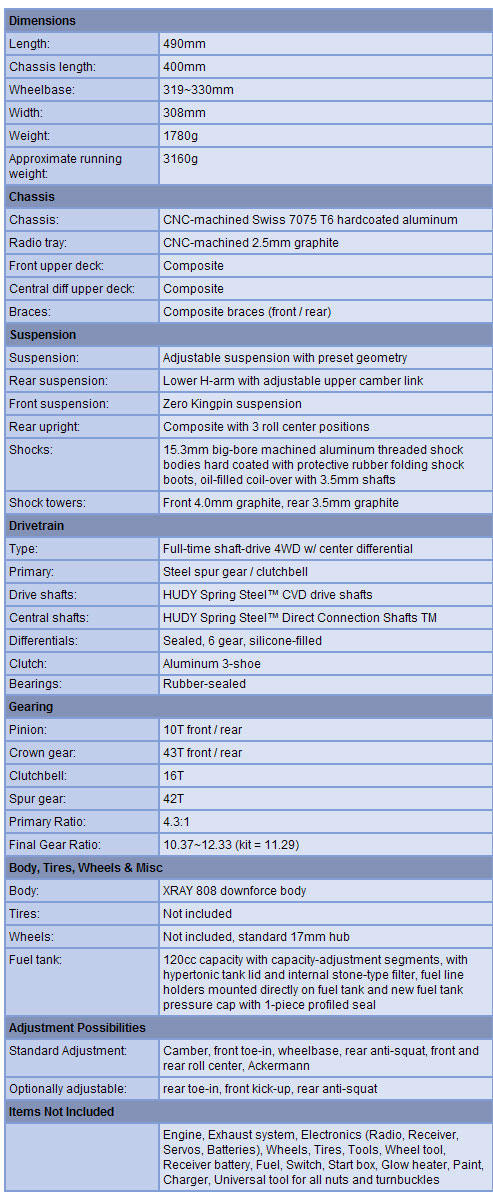

Improved Weight Balance

One of the most significant improvements in the handling of the 808 is the improved weight balance. With the new longer chassis and new suspension concept (which is not overly-sensitive on weight load) this allowed the engine and central differential to be placed more forward. The more forward weight placement – along with the new suspension concept – greatly improves the balance of the car during on- & off-power jumps, and driving through the corners it allows for greater rotation of the car which results in increased cornering speed.

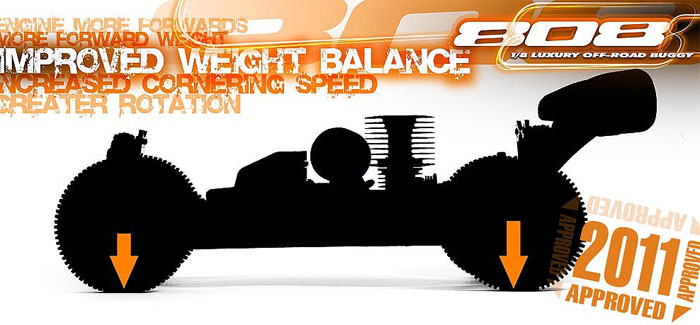

Centralized Design

With the narrow chassis design, all the internal components were repositioned. The engine was placed as close to the centerline as possible while still keeping the center drivetrain in the most effective locations. To balance the weight of the engine, muffler, and fuel tank, the center differential was placed more to the right with the electronics strategically placed in a curved shape around the central differential. All this helps to keep the weight as close to the center as possible. The all-new centralized design improves side-to-side balance.

CVD Driveshafts

The CVD drive shafts are lighter yet still are the strongest that a buggy can be equipped with. All four CVD drive shafts are manufactured from exclusive HUDY Spring Steel™, the unique self-developed highest-strength material.

The CVD wheel axles are carried more safely in the steering blocks and rear uprights thanks to greater distances between ball-bearings. Additionally, the CVD assemblies are very secure and safe due to the connecting pin (which connects the shaft to the wheel axle) being located within a ball-bearing, thus ensuring that the pin will never fell out and preventing drive shaft disconnections.

The wheel axle part of the CVD is hand ground for maximum precision to ensure a perfect precise fit in both suspension ball-bearings… guaranteeing a perfect wobble-free fit and rotation.

Differentials

Rubber-sealed composite differential housings are manually precision ground after the molding process to guarantee a perfect fit with no vibration. Differential gears are made from pressed steel, heat treated, and machined for ultra-precision and smooth operation.Diff outdrives are made from premium HUDY Spring Steel™ and the central diff outdrives are individually ground for highest precision. The diff outdrives are specially-hardened to increase the lifespan, and the diff outdrive area which is inserted into ball-bearing is additionally ground to ensure a very tight fit and precise rotation. The openings of the diff outdrives were designed to keep the drive shafts in the diff outdrives even during maximum suspension downtravel.

Wheel Axles

Wheel axles and wheel nuts are made from lightweight yet super-strong aircraft aluminum, hard-anodized for increased lifespan and low wear. The new suspension is slightly narrower which enables the use of optional offset wheel axles for fine-tuning your 808 for different racing conditions.

Diff Gears & Drivetrain Ratio

Diff main gears are manufactured from HUDY Gear Steel on a precision manual gear machine. This material was specially formulated and developed for use in gears. All gears are hardened to provide the longest possible lifespan.

A wide range of different gears — spur gear, clutchbell, crown gear — is available for perfect set-up and adjustment for particular racing conditions.

Clutchbells are available in sizes of 15T, 16T, and 17T.

Spur gears are available in a range of 41T, 42T, and 43T.

The drivetrain ratio is all-new for the 808, allowing for more aggressive acceleration, and aggressive yet easier handling.

Front and rear differentials feature 43T crown gears with 10T pinions for a 4.3:1 primary ratio.

The central differential features 42T spur gear with a 16T clutchbell for a 11.29 internal ratio.

The final ratio of the 808 is within the range of 10.37–12.33.

Center Differential Access

Access to the center differential is super easy by releasing the upper deck with only four screws. The lower center diff housing is designed to accommodate optional spur gears and the stands were lowered by 2.5mm to keep the weight as low as possible and allow smaller central diff gears to be used. The center diff housing stands hold the effective brake system.

1-piece Electronics Assembly

The 1-piece electronics assembly is very compact and can be quickly & easily removed for servicing and cleaning. You need only to release a few screws from the bottom of the chassis to remove the entire electronics assembly from the car.

The large molded radio box features a very clean design and layout that places the weight in key areas for proper balancing. The batteries are placed along the centerline of the chassis, and the lightweight receiver is placed on its side. The very easy-to-access radio box is mounted on the side of the radio plate and is releasing by only a few screws.

For racers not using a radio switch, a handy molded cover is included to help guarantee a leak-free radio box. The tight antenna tube holder ensures that the antenna tube stays attached even if the car flips.

The radio box was redesigned to fit to the new chassis, and the battery cover was redesigned to hold the batteries more securely.

With the new centralized design concept, the steering stands were narrowed and placed as close to the center as possible using very lightweight aluminum standoffs. The very narrow steering plate is precision-machined from high-grade graphite, thus reducing unnecessary weight. The steering plate features several different Ackermann settings for precision steering setup.

The dual steering system rides on lightly-oiled ball-bearings, providing super-smooth and super-fast steering action. The strong servo saver spring ensures that steering will be very precise in all conditions, while still being soft enough to ensure that crash energy will not be transferred to the servo. The strength of the servo saver can be easily adjusted via an adjustment collar; the collar is hard-anodized to prevent thread stripping even in dusty conditions.

HUDY Spring Steel™ Steering Turnbuckles

All turnbuckles in the 808 are manufactured from special HUDY Spring Steel™ material for turnbuckles, resulting in stronger turnbuckles with a tougher core. A handy turnbuckle tool is included.

With the narrow steering plate and narrow steering stands, the turnbuckles were appropriately resized and elongated. Relieved steering ball-joints fit better into the wheels.

Newly-redesigned Big-Bore Shocks

Off-road performance depends very highly on perfectly-working shock absorbers. As such, all components and pieces of the 808 shocks were completely redesigned to obtain the best possible performance and durability: shock bodies; pistons; shock cap; membranes; lower shock collar; rubber boots; internal shape; alu cap; springs.

The most significant improvement is the bore of the shocks, which was increased to allow for a higher volume of oil to flow for improved damping characteristics. The new big-bore shock pistons were designed and manufactured with a special molding process to ensure optimum tolerance and roundness of the pistons so that they move freely and very precisely inside the shock body.

The front and rear shocks can be mounted in multiple positions on the shocktowers and arms; these positions were thoroughly tested and analyzed both in virtual reality as well on tracks to offer the widest possible range of shock positions. This guarantees sufficient suspension travel and best set-up for either flat European-style tracks or large bumpy US-style tracks.

Shock Parts

The oversized big-bore shocks feature 18.5mm external-diameter shock bodies, externally threaded with an adjustable collar for spring preload adjustment. The shock bodies are hardcoated and feature a new 1-piece alu shock cap.The large 15.3mm inner diameter of the shock bodies ensures proper and consistent oil flow through the perfectly-round pistons, which moves very precisely inside the smoothly-finished interior of the shock body. The result is more consistent damping characteristics.

The new big-bore pistons are manufactured from well-proven specially-formulated composite material to provide smoother action and durability. The well-proven molding production process is used to ensure perfect roundness of the pistons after production, so that the pistons will move perfectly inside the shock bodies for identical shock action in all four shocks.

The new shock membranes are now wider to fit the new big-bore shocks. The material has been also improved to guarantee the same damping characteristics from the beginning of the race to the end even after excessive overloads.

The lower shock assembly ensures that the shock rod will move freely inside the shock body while at the same time minimizing oil leakage and keeping dirt away. Two shock O-rings – manufactured from a superior silicone compound to allow ultra-free movement of the shock rod while still maintaining a tight seal – are installed in the lower part of the shock body and are secured with composite shims. The entire lower shock assembly is secured with a new lower aluminum shock cap which makes assembly/disassembly quick and easy. The aluminum lower cap features an internal protective “dust foam” which keeps dirt out.

The shock shafts are thick and robust to ensure they can handle abusive racing conditions and big jumps. The 3.5mm thick shock shafts are precisely machined from special high-tensile steel and afterwards are ground for a super-smooth surface to ensure free and smooth movement of the shock shafts in the shock bodies.

XRAY Premium Silicone Oils

The 808 includes new XRAY Premium Silicone Oils manufactured in Europe by a specialized premium silicone oil manufacturer; these new oils were exclusively created for XRAY. Each batch of premium oil is laboratory tested and calibrated to ensure the highest possible consistency and quality batch-to-batch. Based on industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY Team Drivers, you can be sure that the oils you will get for your car will be exactly same as the oils used by the factory racing team, thus ensuring very exacting setups and handling.

Clutch System

The clutch flywheel is CNC-machined from high-quality Swiss 7075 T6 aluminum. The clutch features three (3) lightweight 1.71g aluminum shoes and a set of hard clutch shoe springs. A HUDY Spring Steel™ clutch nut is included, along with necessary shims and hardware. The flywheel brass collar is not included and is available with every engine supplier or optionally from XRAY.

Oversized Clutch Bearings

The 808 clutchbell features unique oversized ball-bearings designed and engineered by XRAY. Replacing the standard 5x10 bearings with balls of only 1.3 mm, the oversized 808 clutch bearings are 5x12 with balls of size 2.0 mm and with extra-thick bearing walls. This translates to higher load carrying capabilities which will increase the life of the bearings and reduce the risk of clutch bearing failure during long runs. The ball-bearings come with special high-temperature resistant grease to ensure proper lubrication during high-revving engine operations and long runs.

Engine Mounts

High-grade CNC-machined aluminum engine mounts are machined from lightweight alloy and help to dissipate engine heat. The engine mounts are easily adjustable from the bottom of the chassis to obtain proper gear mesh.

The engine mount is all newly designed, it is longer and goes up to the front engine bearing which provides higher reinforcement of the chassis in the longitudinal direction and in jumps will minimize chassis bending between the clutchbell and spur gear.

Brake System

The 808 features the well-proven high-performance braking system that is so strong and precise and dependable that is makes slowing and stopping a profoundly exhilarating experience. Coupled with the car’s balanced load distribution, the extraordinary control imparted by the braking system gives you complete confidence as you pitch the car into corners.

XRAY focused on all of the smallest details when designing the brake system. The laser-cut, precision flat-ground ventilated steel brake disk allows for fade-free braking in conjunction with the special high-grip Ferodo® brake pads installed on laser-cut backing plates. The brake disk is small, slim, and very light. The precision hand-grinding allows true, wobble-free rotation. Brake inputs are transferred precisely to the brakes via rigid high-precision machined brake cams. The brake disk and brakepad backing plates are specially heat-treated for maximum lifespan.

Fuel Tank and Air Filter

The fuel tank has an integrated stone filter and molded-in splashguard to protect the brakes from fuel spillage. The tank is mounted with rubber grommets to absorb vibration. Small composite holders secure thick 5.5mm silicone fuel tubing.The smooth-flowing and efficient air filter is made from two parts. Air filter oil is included as standard. The universal rubber elbow allows fitment to most standard 1/8 buggy engines.

Anti-roll Bars

Anti-roll bars are included to stabilize the car at both front and rear. The 808 features new shorter anti-roll bars which also have a different angle to accommodate mounting to the new suspension. The roll bars are easily mounted to the diff cases and can be adjusted through the adjustable linkages.

Both front and rear anti-roll bars have a thickness of 2.4mm. Anti-roll bar wires of different thickness are optionally available for fine-tuning your set-up.

Wing

The aerodynamic rear wing is molded from a very flexible yet virtually unbreakable composite mixture. All edges are reinforced at critical areas to prevent cracking or breakage. The rear wing holders are mounted firmly to the rear shock tower. The rear wing holders offer many different wing-mounting positions for increased adjustability at different tracks.

Adjustment Possibilites

The 808 features fully-adjustable front and rear suspension geometry: caster, camber, toe, anti-dive, anti-squat, ride height, droop, track-width, Ackermann and roll centers. For easy and fast adjustment we recommend using set-up tools and accessories from HUDY, the world leader of RC tools.